Our Product

Fiber Glass are considered a better alternative than steel due to their low density and light weight, which make them ideal for use in lightweight products with high strength. The tensile strength of glass fibers is about 40% better than that of steel, and it is easy to cut to the desired length.

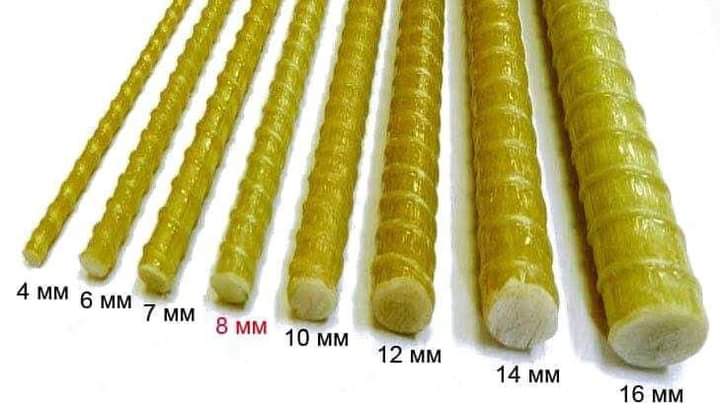

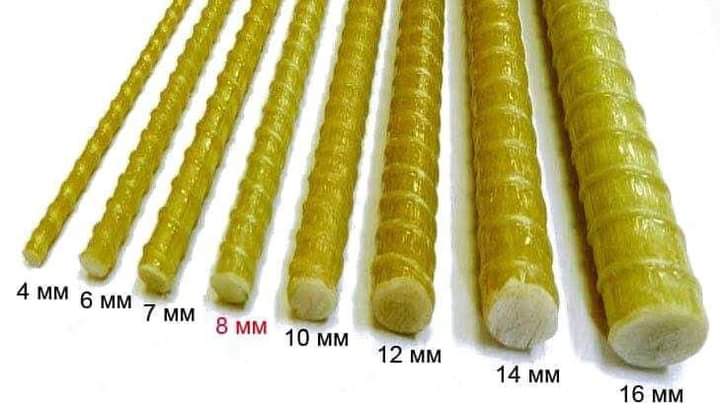

Fiberglass Reinforced Polymer Rebars

Fiberglass Reinforced Polymer (FRP) Rebars are high-performance, corrosion-resistant reinforcements designed for sustainable and durable construction projects. They are lightweight, strong, and well-suited to harsh environments, making them ideal for infrastructure, industrial, and residential applications.

Usage of Fiberglass Reinforced Polymer Rebars

Infrastructure Projects: Commonly used in bridges, highways, and marine structures where exposure to moisture and salt can lead to steel corrosion.

Industrial Construction: Suitable for facilities where reinforcement may contact chemicals that degrade traditional steel.

Residential and Commercial Buildings: Perfect for foundations, walls, and floors due to their lightweight yet strong nature.

Electrical and Telecommunications Structures: Non-conductive properties make them ideal for projects requiring high electrical insulation.

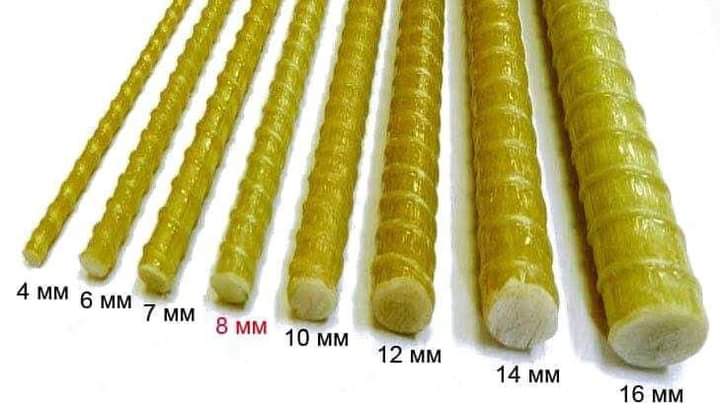

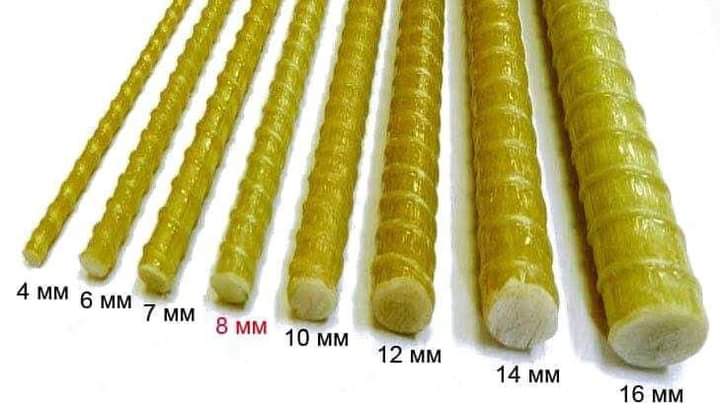

Fiberglass Reinforced Polymer Rebars

Fiberglass Reinforced Polymer (FRP) Rebars are high-performance, corrosion-resistant reinforcements designed for sustainable and durable construction projects. They are lightweight, strong, and well-suited to harsh environments, making them ideal for infrastructure, industrial, and residential applications.

Usages:

- Infrastructure Projects: Commonly used in bridges, highways, and marine structures where exposure to moisture and salt can lead to steel corrosion.

- Industrial Construction: Suitable for facilities where reinforcement may contact chemicals that degrade traditional steel.

- Residential and Commercial Buildings: Perfect for foundations, walls, and floors due to their lightweight yet strong nature.

- Electrical and Telecommunications Structures: Non-conductive properties make them ideal for projects requiring high electrical insulation.

Fiberglass WireMesh

Fiberglass Mesh is a lightweight, durable, and corrosion-resistant material made from woven fiberglass yarns. It is commonly used in construction and reinforcement applications due to its excellent tensile strength, flexibility, and resistance to cracking, shrinkage, and environmental stress.

Usage of Fiberglass Wiremesh

- Wall Reinforcement: Frequently used in plastering and stucco applications to prevent cracks and enhance wall durability.

- Flooring Applications: Provides additional strength and stability in screeds, underlayment, and tile installations.

- Waterproofing Systems: Functions as a reinforcement layer in waterproof coatings, ensuring longevity and protection.

- Thermal Insulation Systems: Integral in External Thermal Insulation Composite Systems (ETICS) to improve durability and weather resistance.

- Industrial Applications: Employed in joint tapes and as reinforcement in composite materials across various

Fiberglass WireMesh

Fiberglass Mesh is a lightweight, durable, and corrosion-resistant material made from woven fiberglass yarns. It is commonly used in construction and reinforcement applications due to its excellent tensile strength, flexibility, and resistance to cracking, shrinkage, and environmental stress.

Usages:

- Wall Reinforcement: Frequently used in plastering and stucco applications to prevent cracks and enhance wall durability.

- Flooring Applications: Provides additional strength and stability in screeds, underlayment, and tile installations.

- Waterproofing Systems: Functions as a reinforcement layer in waterproof coatings, ensuring longevity and protection.

- Thermal Insulation Systems: Integral in External Thermal Insulation Composite Systems (ETICS) to improve durability and weather resistance.

- Industrial Applications: Employed in joint tapes and as reinforcement in composite materials across various industries.

Fiberglass Stirrup and Bored pile

Fiberglass Stirrup is a lightweight, corrosion-resistant reinforcement material made from fiberglass, used to replace traditional steel stirrups in various construction applications. Bored Piles, on the other hand, are deep foundation elements created by drilling a hole and filling it with reinforced concrete, designed to support heavy structural loads and transfer them to stable soil layers or bedrock. Together, they form a robust combination for durable and efficient construction solutions.

Usages:

- Structural Reinforcement: Fiberglass stirrups provide additional strength in beams and columns, while bored piles ensure foundational stability for large structures.

- Corrosion-Resistant Projects: Ideal for environments like marine structures or wastewater treatment plants, where fiberglass stirrups resist corrosion, and bored piles offer durability against moisture.

- High-Rise and Infrastructure Projects: Bored piles provide strong foundational support for tall buildings, bridges, and tunnels, while fiberglass stirrups enhance the structural integrity of reinforced concrete elements.

- Electrical and Magnetic Sensitivity: Fiberglass stirrups are suitable for projects requiring non-conductive and non-magnetic properties.

- Areas with Weak Soil: Bored piles are perfect for transferring loads to deeper, stable layers in regions with poor surface soil conditions.

Fiberglass Stirrup and Bored pile

Fiberglass Stirrup is a lightweight, corrosion-resistant reinforcement material made from fiberglass, used to replace traditional steel stirrups in various construction applications. Bored Piles, on the other hand, are deep foundation elements created by drilling a hole and filling it with reinforced concrete, designed to support heavy structural loads and transfer them to stable soil layers or bedrock. Together, they form a robust combination for durable and efficient construction solutions.

Usages:

- Structural Reinforcement: Fiberglass stirrups provide additional strength in beams and columns, while bored piles ensure foundational stability for large structures.

- Corrosion-Resistant Projects: Ideal for environments like marine structures or wastewater treatment plants, where fiberglass stirrups resist corrosion, and bored piles offer durability against moisture.

- High-Rise and Infrastructure Projects: Bored piles provide strong foundational support for tall buildings, bridges, and tunnels, while fiberglass stirrups enhance the structural integrity of reinforced concrete elements.

- Electrical and Magnetic Sensitivity: Fiberglass stirrups are suitable for projects requiring non-conductive and non-magnetic properties.

- Areas with Weak Soil: Bored piles are perfect for transferring loads to deeper, stable layers in regions with poor surface soil conditions.

Fiberglass Profile

Fiberglass Profile is a versatile, lightweight, and corrosion-resistant material made from fiberglass, used in a variety of construction and industrial applications. It is typically molded into specific shapes such as beams, channels, and angles, offering superior strength-to-weight ratio and resistance to environmental factors.

Usages:

- Structural Applications: Used in building frames, supports, and structural reinforcements where corrosion resistance and lightweight properties are critical.

- Transportation Industry: Ideal for vehicle components, such as panels and frames, due to its durability and resistance to harsh weather conditions.

- Electrical and Communication Systems: Employed in creating non-conductive profiles for safe and efficient electrical and telecommunication installations.

- Marine and Offshore Structures: Perfect for use in shipbuilding, docks, and offshore platforms where resistance to saltwater corrosion is essential.

- Architectural Design: Used in creating aesthetically appealing, durable, and weather-resistant profiles for facades, windows, and roofing systems.